Webinar | How to optimize your gas turbine outage?

Maintaining gas turbines

Take control and reduce costs

Is it possible to reduce the cost of gas turbine maintenance without compromising on safety or quality? Yes, it is. In this 55-minute webinar, we tell you how.

Timing and details below.

Session 1 and session 2 are identical, please only register for one session. Registration with a professional e-mail address is required, no gmail, hotmail, yahoo, …

Programme

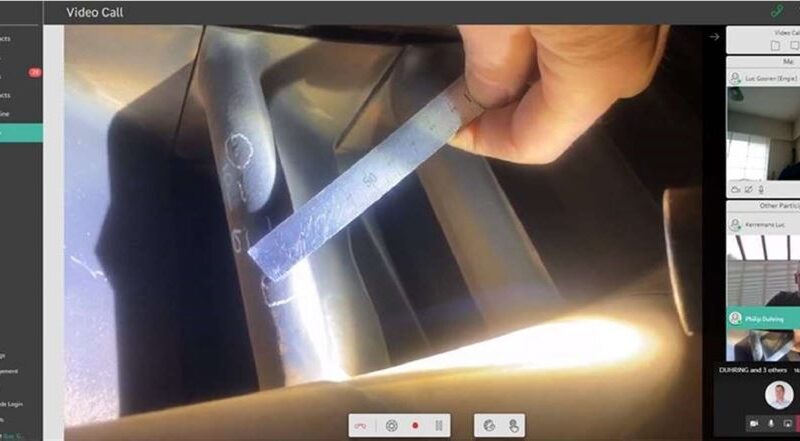

1 - Remote inspection: a viable strategy

Traveling to installations or having independent experts on-site to carry out turbine inspections in the normal way is a big challenge, especially when there’s a worldwide pandemic. Remote inspections are a quick, obvious, and attractive alternative, and are not too expensive. But can they achieve everything you need, and with the same level of detail as traditional onsite inspections?

In Part 1 of this new webinar, we take a look at how remote inspections can bring significant added value, and how they can be integrated into cost-effective maintenance strategies, with real-world examples.

2 - Extending maintenance intervals: avoid the risks

In the current market environment, there is an urgent drive to reduce costs. With spare parts representing up to 85% of all maintenance costs, extending maintenance intervals beyond the conservative schedules recommended by original equipment manufacturers (OEMs) is an approach well worth examining. But there are risks associated with it, such as unplanned stops or even failures — and insurers will need to be on board too.

In Part 2, we highlight practical examples of how risk can be assessed and mitigated, and how to satisfy OEMs and insurers.

3 - Maintenance downtime: a critical opportunity

Downtime for maintenance is both a risk and an opportunity. It’s a risk because changes made during downtime could have a negative effect on process performance. It’s an opportunity because, by measuring certain process parameters before and after shutdown, modifications can be more informed and targeted. Control the risks and you can take full advantage of the opportunities to achieve better performance.

In the webinar’s final part, we share best practice on how to pro-actively identify potential risk points, minimize any knock-on performance consequences, and optimize start-up for trouble-free operation.

Practical info

Webinar duration: +/- 55-minute

2 sessions: Please only register for one session.

Session 1 and 2 are identical.

Not available on the day of the webinar?

No problem, you can register anyway and we

will send you the recording and slides afterwards.

Meet the experts

Luc Gooren, Product Manager and Gas Turbine Expert, ENGIE Laborelec.

Beginning his gas turbine career in 2006, Luc managed product design and development at Sulzer Turbo Services in the Netherlands, specializing in repair methods. He was also involved in developing and promoting the use of non-OEM replacement parts for a wide range of heavy-duty turbines. Luc joined ENGIE Laborelec in 2016, assisting operators to optimize maintenance and troubleshoot heavy-duty gas turbines worldwide. He is also active in R&D, including leading a demonstration project studying hydrogen co-combustion in an industrial gas turbine.

Pieter-Jan Stockmans, Senior Project Manager, Thermal Generation, ENGIE Laborelec.

With master’s degrees in Electro-Mechanical Engineering and Energy Engineering, Pieter-Jan is a highly experienced specialist in power plant performance and currently heads up business development for Laborelec’s Thermal Generation services in Europe. He has conducted and coordinated numerous process optimization programmes and projects in power plants throughout the world. As Technology Manager for Process Performance at ENGIE Laborelec, he worked alongside operators to set objectives and develop effective operational and maintenance strategies.

Bring your own cases and get answers to your questions.

Questions bienvenues | Stel je vraag | Domande benevute | Preguntas bienvenidas

You are most welcome to ask questions during the webinar and bring specific cases for discussion. Our experts will offer their advice, and any questions not answered during the webinar will be handled by email follow-up. Questions can be asked in English, French, Dutch, Spanish or Italian.