The generator is a critical component of any wind turbine, so periodic assessment of its health is vital, especially during end-of-warranty (EOW) inspections. ENGIE Laborelec provides comprehensive inspection services for wind turbine generators, and reliable condition assessment.

Degradation phenomena

Even though the generator is critical to wind turbine operation, it is often left badly served or overlooked in maintenance programmes or during end-of-warranty (EOW) inspections. Experience shows that multiple degradation phenomena can occur over the years of operation inside the generator. Possible issues include faulty stator or rotor windings or degradation of the insulation, significantly impacting the component’s remaining lifetime.

Generator inspection services

ENGIE Laborelec inspects both onshore and offshore wind turbine generators. We conduct:

• onsite inspection during periodic outages,

• onsite assessment as part of end-of-warranty inspections (EOW),

• inspections as part of failure root cause analysis (RCA).

We assess the risk of generator failure and whether corrective actions are needed, based on our findings.

We also assist operators during site acceptance tests (SATs) and in discussions with OEMs.

Benefits

Identifying issues early

Component degradation can be detected at an early stage, avoiding unplanned downtime and costly repairs.

Complete, accurate EOW punch lists

Complete and accurate end-of-warranty punch lists are quickly established, based on our report.

Improving maintenance

Our assessment allows operators to optimize maintenance and investment programmes.

Added value

Backed up by decades of experience assessing the condition of industrial generators, we carry out OEM-independent generator inspections at power stations, industrial sites, and onshore and offshore wind farms all over the world.

How it works

As part of ENGIE Laborelec’s onsite generator inspection, we may conduct the following activities:

Visual inspection

Assessing general condition and identifying potential sources and causes of contamination.

Identifying winding issues

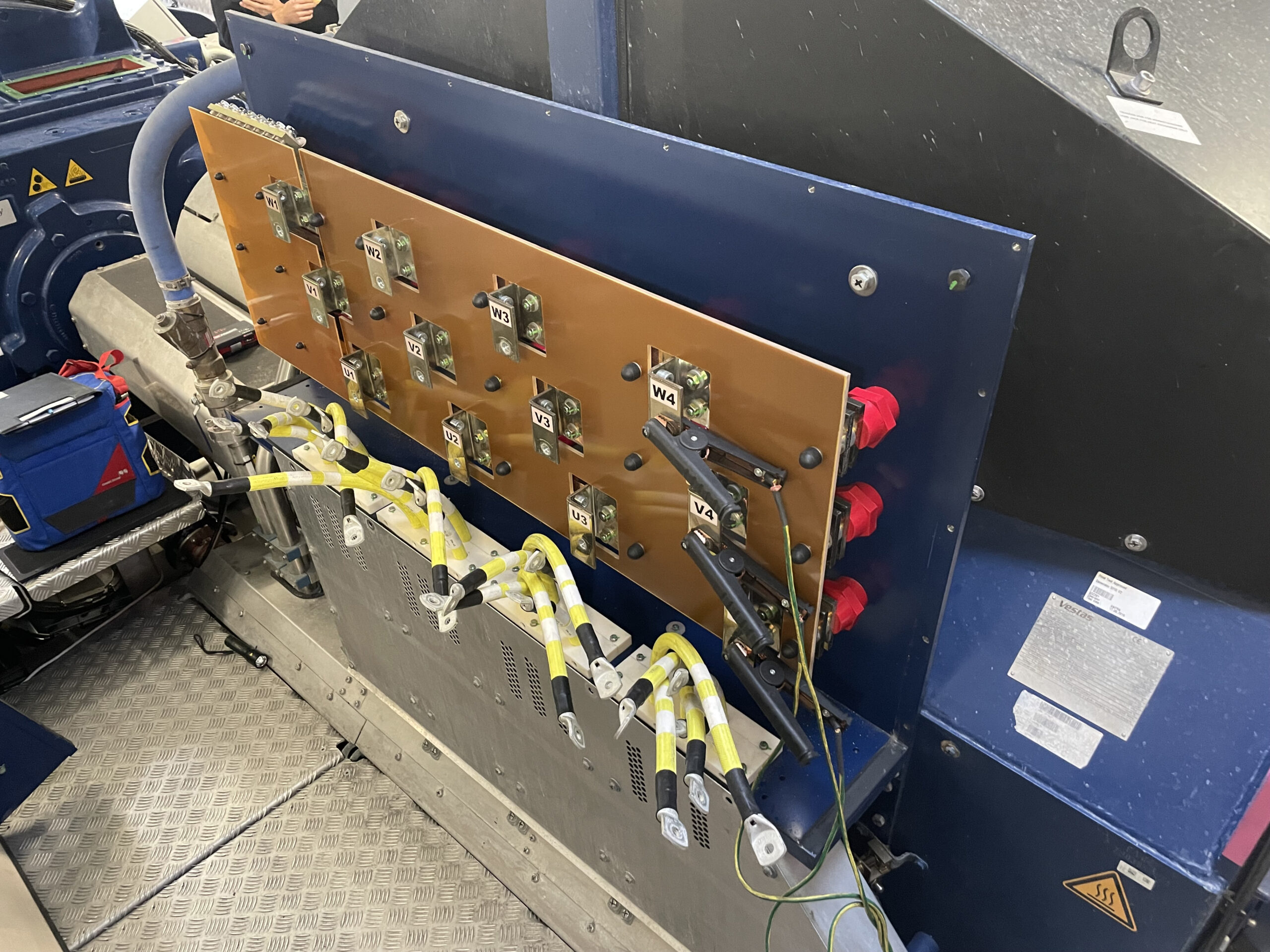

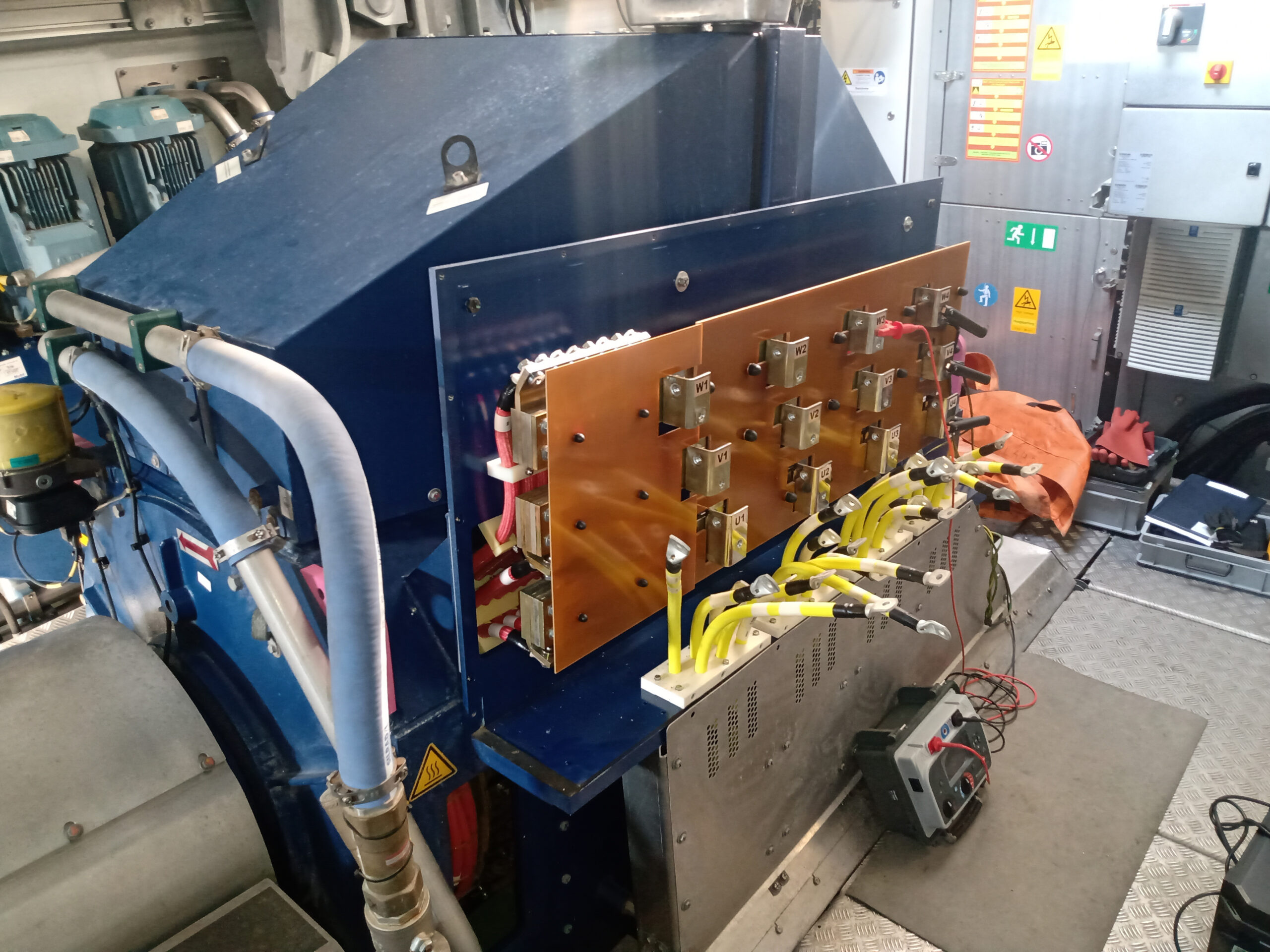

DC winding resistance measurement and testing to reveal issues such as copper cracks or poor connections,

Identifying insulation problems

Measurements on low- and medium-voltage generators, including insulation resistance, polarization index, winding resistance and, in some cases, step high-voltage tests to identify issues and assess severity. We may also carry out advanced measurements, such as partial discharges, on medium-voltage generators.

Endoscopic inspection

Where access to the generator is good and inspection holes are available.

All inspections and measurements are carried out using a compact portable measuring toolset easily transported to the turbine nacelle, both on- and off-shore.

Assessing the machine's health

We assess the machine’s condition based on our inspections, with all factors considered. To give an overall indication of generator winding and insulation health, we have also developed a health score, calculated from the results of electrical measurements. This allows operators to compare the condition of machines of identical design or serving the same function, and finetune the maintenance strategy of large wind turbine fleets.