Webinar | How to improve the maintenance strategies for power generators using on-line condition monitoring

Power generators age with operation and this is accelerated by the flexible operation dictated by the energy transition. Predictive maintenance, based on monitoring the condition of the stator and rotor windings, is of strategic importance.

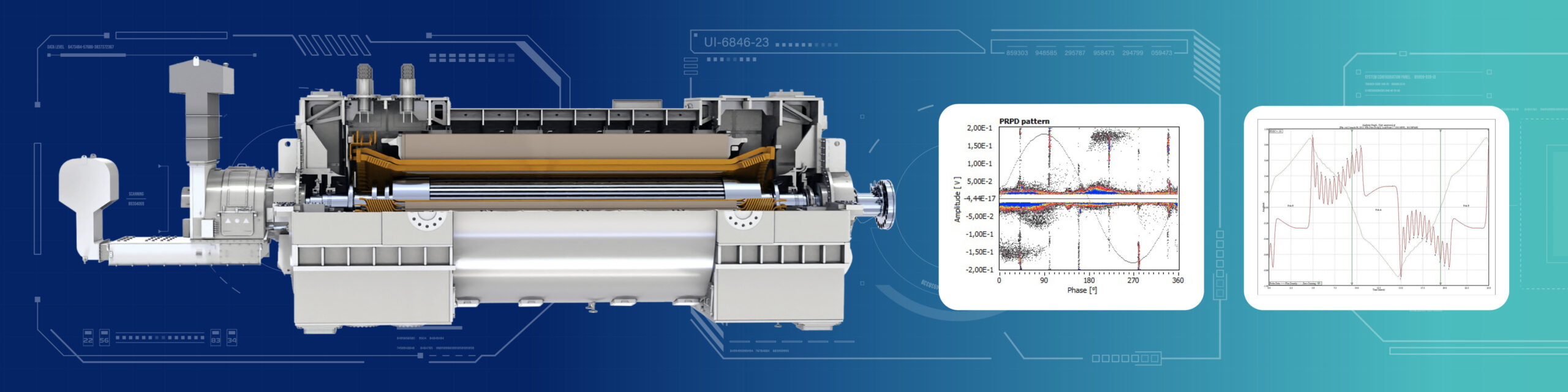

In this webinar a Laborelec expert examines, through case studies, the advantages of monitoring partial discharges to find out what types of degradations are active on the stator winding. He also discusses how combining rotor flux and shaft vibration monitoring is a powerful way of detecting shorted turns and how they evolve.

Programme

Jean-Michel Meunier, Technical Leader in Electrical Rotating Machines at ENGIE Laborelec discusses the answers to the following questions:

- What are partial discharges and what impact do they have on stator winding insulation ageing?

- How are partial discharges monitored and what can be learned from analysis of the results?

- What causes short-circuits inside rotor windings and what are the consequences for generator operation?

Want to watch the webinar?

What happens to my personal data?

This form collects a small quantity of personal information to help ENGIE Laborelec better understand the needs and areas of interest of its audience, and adapt the company’s offer of webinars, training courses and technical services. In some very limited circumstances, we may use it to contact you with carefully selected content which we think may be helpful for your business or activities. Personal data will be treated according to the ENGIE privacy statement and will be deleted after 12 months.