Enhancing power plant chemistry maturity

Below-standard chemistry causes a significant number of incidents at power plants worldwide, leading to unplanned outages and increased operating costs. An independent review of plant chemistry installations and processes allows operators to align with industry best practices, protecting plant performance and making significant cost savings.

WHY - The importance of sound chemistry management

Experience shows that around 30% of power plants suffer a major chemistry-related incident within ten years of operation, leading to repair and unavailability costs running into several millions of euros. Even minor incidents such as slight contamination of the water-steam cycle could significantly impact plant performance and maintenance costs, for example due to accelerated corrosion. It is therefore of paramount importance for power plant operators to bring their chemistry management up to standard.

WHAT - Improving design and practices

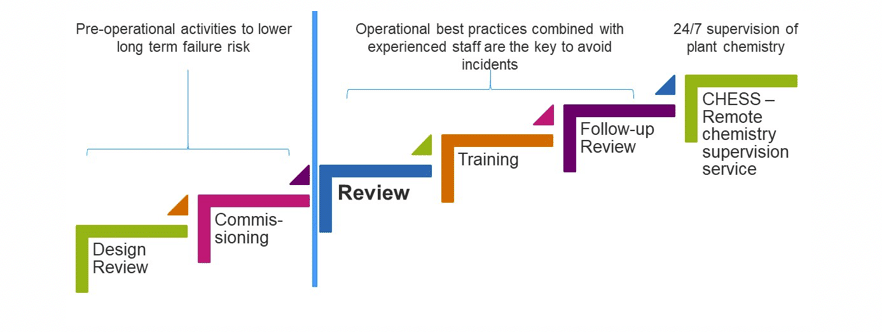

ENGIE Laborelec offers a proven maturity program to help power plant operators achieve operational excellence in how they manage their chemistry. In new power plants, the program begins with an in-depth design review and commissioning assistance. In installations that are up and running, a chemistry review is carried out. Staff can then be trained and a follow-up review carried out. A continuous remote chemistry supervision service rounds out the maturity program.

Benefits & added value

Improved chemistry management avoids unplanned downtimes and reduces risks. While unplanned downtimes due to chemistry can cost up to €100,000 per day, losses due to a major incident could run into the millions.

Our experts make sure that plant chemistry installations are brought up to the highest standard achievable and that the related processes are aligned with industry best practices.

Our evaluations, advice and support services are totally vendor-independent, meaning that we always serve your interests, not those of your equipment supplier.

ENGIE Laborelec has more than 50 years’ experience reviewing and improving chemistry installations and practices in all types of power plants worldwide.

In addition to our competence in chemistry, we engage comprehensive expertise in a broad spectrum of technical fields, including materials technology, enabling cross-linked analysis of failure events.

How it works

Our experts carry out an on-site mission to evaluate and analyze key installations, and related chemistry practices, to develop and deliver a tailor-made improvement plan. Evaluating the quality of key installations and processes

After processes: Demineralization unit

We evaluate the pre-treatment, treatment and polishing processes, the quality and compatibility of the makeup water, the chemical dosing installation, and the monitoring program.

Water-steam cycle

We evaluate the chemical treatment program and the dosing installation, the contamination risk, and the effectiveness of the online monitoring system. We also analyze past operational data, as well as any incidents that may have occurred. Specific chemistry issues, such as flow-accelerated corrosion, iron transport or copper issues may also be analyzed.

Cooling circuits

We evaluate anti-scaling and biocide treatment, the quality and compatibility of the makeup water, the dosing system, and the monitoring program. During these evaluations, we also identify opportunities to reduce operational costs and improve performance.

Developing an action plan

Based on the findings, we develop action plans for each installation and present them on-site. Actions may include modifications to installations, defining and implementing more appropriate treatment, control and monitoring programs, and improving procedures and practices. Actions related to the water-steam cycle specifically target lowering the risk of different types of corrosion and chemistry-related boiler failures.

Chemistry review as the cornerstone

The cornerstone of ENGIE Laborelec’s chemistry maturity program is the chemistry review service to evaluate and improve the management and quality of chemistry-related installations and processes. We carry out a comprehensive review of all chemistry-related equipment and activities, including demineralized water production, the water-steam cycle, and cooling circuits. Based on the findings, our experts develop an action plan to achieve world-class standards in power plant chemistry management. This could include equipment fine-tuning as well as improving chemistry-related procedures, treatment programs and practices.