The phenomenon of Potential Induced Degradation (PID) negatively affects the performance of many PV installations around the world. PID leads to the progressive degradation of modules and strings, eventually representing a serious threat to the performance of the whole installation. ENGIE Laborelec offers a service to identify modules affected by PID, assessing the long-term impact so that an appropriate remediation project can be set in motion.

WHY

A THREAT TO THE PV PLANT’S BUSINESS CASE

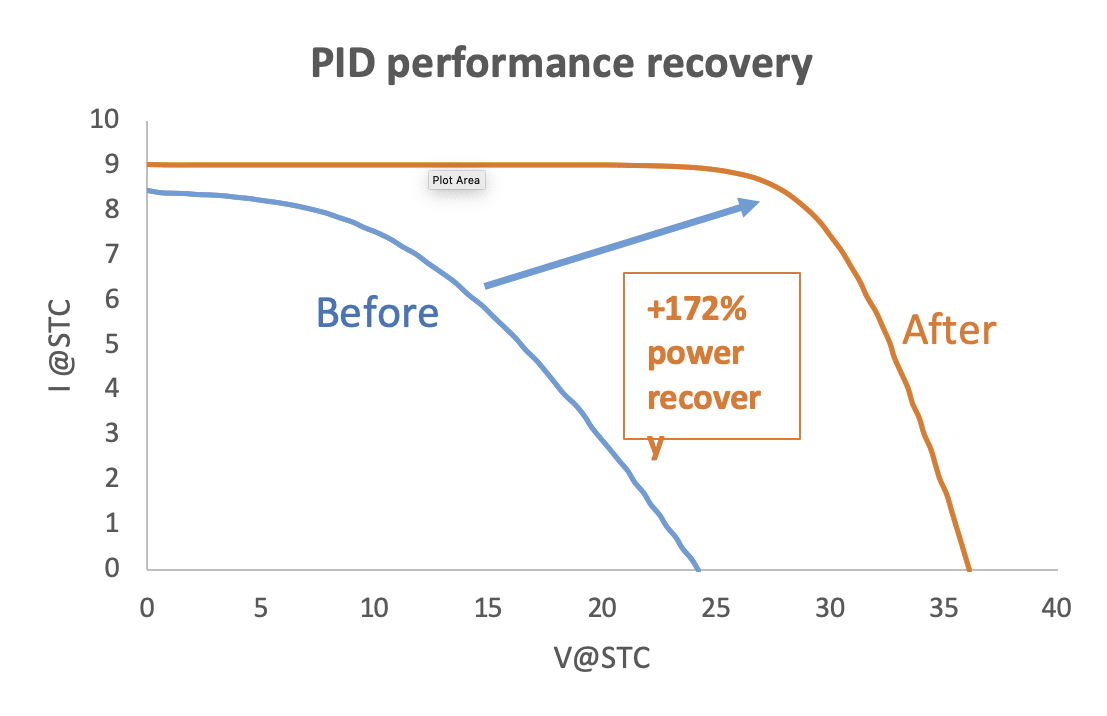

While Potential Induced Degradation (PID) is still a little-known phenomenon among PV plant operators, tests have revealed that about 80% of commonly used models are susceptible to it. The process typically occurs a few years after commissioning, beginning at the periphery but gradually affecting an increasing number of cells and modules. Over time, affected modules may lose up to 80% of their power generation capacity. If the issue is not addressed appropriately and in good time, it poses a serious threat to the profitability of the PV plant. The ENGIE Laborelec PID remediation service comes to the rescue.

WHAT

RESTORING CAPACITY AND EXTENDING LIFETIME

Our experts carry out inspections and take measurements to identify where PID is present and quantify the resulting power loss. We then analyze the data against the plant’s technical specifications to predict the impact of PID progression on plant performance over the long term. Finally, we propose a tailored remediation solution to restore plant capacity and extend useful lifetime. The method could involve replacing modules or putting in place a PID mitigation solution, depending on the level of degradation and inverter compatibility.

BENEFITS

Securing long-term performance

The service halts the degradation arising from PID, restores power generation capacity, and extends plant lifetime, securing the plant’s long-term objectives.

ADDED VALUE

Unmatched expertise

ENGIE Laborelec has many years’ experience analyzing solar plants all over the world, ranging from first-generation PV plants to leading-edge bifacial installations. We have tested a wide range of PID mitigation solutions and keep a close watch on the ever-evolving PV market to always advise on the best and most appropriate solutions. Our independence from equipment suppliers means that we can always guarantee the objectivity of our solutions and recommendations.

A durable solution

While investigating the presence of PID, our experts also examine other aspects that might negatively impact plant quality and performance, such as backsheet issues, soiling or unexpected inverter downtimes arising from reduced insulation resistance. This allows for targeted remedial actions.

HOW IT WORKS

PRELIMINARY ASSESSMENT

Based on the technical specifications of the PV plant, we make a preliminary assessment of the PV plant’s susceptibility to Potential Induced Degradation (PID). Where there is significant risk, we propose a more comprehensive assessment.

INSPECTION AND MEASUREMENT

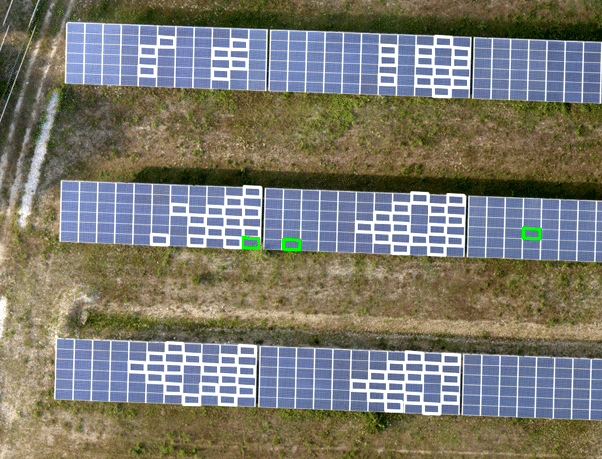

Our experts inspect the solar plant to identify the presence of PID and other known phenomena. If needed, this may include a drone-assisted aerial inspection of the entire plant. Following an initial global diagnosis, we carry out measurements at selected modules and strings to quantify any power loss resulting from PID.

ESTIMATING EXPECTED YIELD LOSS

We analyze the measurement data as well as the technical specifications of the installation to fully understand the severity of the problem and to assess the long-term impact of PID and other identified issues on plant performance. Our report gives asset managers a clear view of the financial impact of the problem allowing them to make informed and calculated decisions to resolve the issues.

SMART REMEDIATION

Depending on the measured power loss and plant specifications we develop and implement a tailored remediation solution to restore plant capacity and extend useful lifetime.